Find Marine Salvage Airbag, Ship Launching Airbag , Rubber Airbag on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

Model No.: FL-M 1259 D1.5*L16m

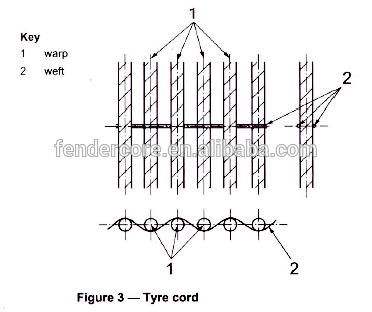

Rubber Airbags, basic body consists of rubber layers, synthetic-cord-reinforced rubber layers, are kind of a cylindrical airbags with hemispherical heads at the both ends. All of these are vulcanized together, and then compress air inside to enable in to roll.

Rubber Airbags, basic body consists of rubber layers, synthetic-cord-reinforced rubber layers, are kind of a cylindrical airbags with hemispherical heads at the both ends. All of these are vulcanized together, and then compress air inside to enable in to roll.  Rubber Airbag Parameter: ( we can supply detailed dimension )

Rubber Airbag Parameter: ( we can supply detailed dimension )Diameter (D): | From 0.5m to 2.8m |

Effective Length (EL): | From 5.0m to 24.0m |

Total Length (TL): | From 6.0m to 25.5m |

Standard Number of Layers: | Usually 4-10 layers |

Loading Capacity: | About 10-40 T/M |

Prior to the airbag production, the outer and inner rubber layers shall be tested to meet criteria in the following table in accordance with the test methods given in the international standard list in the table. While only one satisfactory sample per batch is required for test numbers 1 through 3, all Others must be tested for test numbers 4 through 9 annually. If the first sample fails, two additional sample should be tested. If the additional samples pass the test requirements, the materials will be deemed to have passed the test. Otherwise, the materials will be deemed to have failed the test and another batch of materials shall be selected.

Prior to the airbag production, the outer and inner rubber layers shall be tested to meet criteria in the following table in accordance with the test methods given in the international standard list in the table. While only one satisfactory sample per batch is required for test numbers 1 through 3, all Others must be tested for test numbers 4 through 9 annually. If the first sample fails, two additional sample should be tested. If the additional samples pass the test requirements, the materials will be deemed to have passed the test. Otherwise, the materials will be deemed to have failed the test and another batch of materials shall be selected.  Rubber Airbag Specification:

Rubber Airbag Specification:  Rubber Airbag Test: Unless otherwise specified, test shall be performed under the following conditions: ambient temperature 10-35. Media: dry clean compressed air, and clean fresh water for bursting test. The test should be performed using a full sized airbag. If the airbag is too large to be mounted on the test machine, they test may be performed on a scaled-down airbag. In order to maintain a proper representation of the full-size sample airbag, the diameter of the scaled-down airbag shall be no less than 1/2 of the full sized sample airbag diameter, while the length shall be no less than 3 times the diameter of the scaled-down airbag. Gas-tightness test Without carrying any load, fill the airbag till the internal pressure of the airbag in the following tale. The internal pressure should be recorded and compared with the pressure after 1 hour. The pressure loss should be less than 5% of pressure.

Rubber Airbag Test: Unless otherwise specified, test shall be performed under the following conditions: ambient temperature 10-35. Media: dry clean compressed air, and clean fresh water for bursting test. The test should be performed using a full sized airbag. If the airbag is too large to be mounted on the test machine, they test may be performed on a scaled-down airbag. In order to maintain a proper representation of the full-size sample airbag, the diameter of the scaled-down airbag shall be no less than 1/2 of the full sized sample airbag diameter, while the length shall be no less than 3 times the diameter of the scaled-down airbag. Gas-tightness test Without carrying any load, fill the airbag till the internal pressure of the airbag in the following tale. The internal pressure should be recorded and compared with the pressure after 1 hour. The pressure loss should be less than 5% of pressure.  Rubber Airbag Application: 1.For ship upgrading, conversion or new/repair launching (Ship launching airbags)

Rubber Airbag Application: 1.For ship upgrading, conversion or new/repair launching (Ship launching airbags)

Rubber Airbags Storage: The airbags should be maintained in a dry ventilated room and be protected from light. The airbags should be in a relaxed condition free from tension, compression or other deformation. The airbags should be kept away from any heat source. The airbags should be protected from acids, alkalis, oils or organic solvents.

Rubber Airbags Storage: The airbags should be maintained in a dry ventilated room and be protected from light. The airbags should be in a relaxed condition free from tension, compression or other deformation. The airbags should be kept away from any heat source. The airbags should be protected from acids, alkalis, oils or organic solvents.

Contact us if you need more details on rubber airbag. We are ready to answer your questions on packaging, logistics, certification or any other aspects about ship rubber airbag、dry dock rubber salvage ship airbag. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on rubber airbag. We are ready to answer your questions on packaging, logistics, certification or any other aspects about ship rubber airbag、dry dock rubber salvage ship airbag. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Marine Airbag > Marine Salvage Airbag